Excelerate’s Perforated Pallet Wrap: Revolutionising Supply Chains

Traditional pallet wrap has one big flaw: it traps heat, condensation, and gases around your products. The result? wet packaging, spoiled stock, and costly rewraps.

That’s why more manufacturers are switching to perforated pallet wrap – also known as ventilated or breathable stretch film.

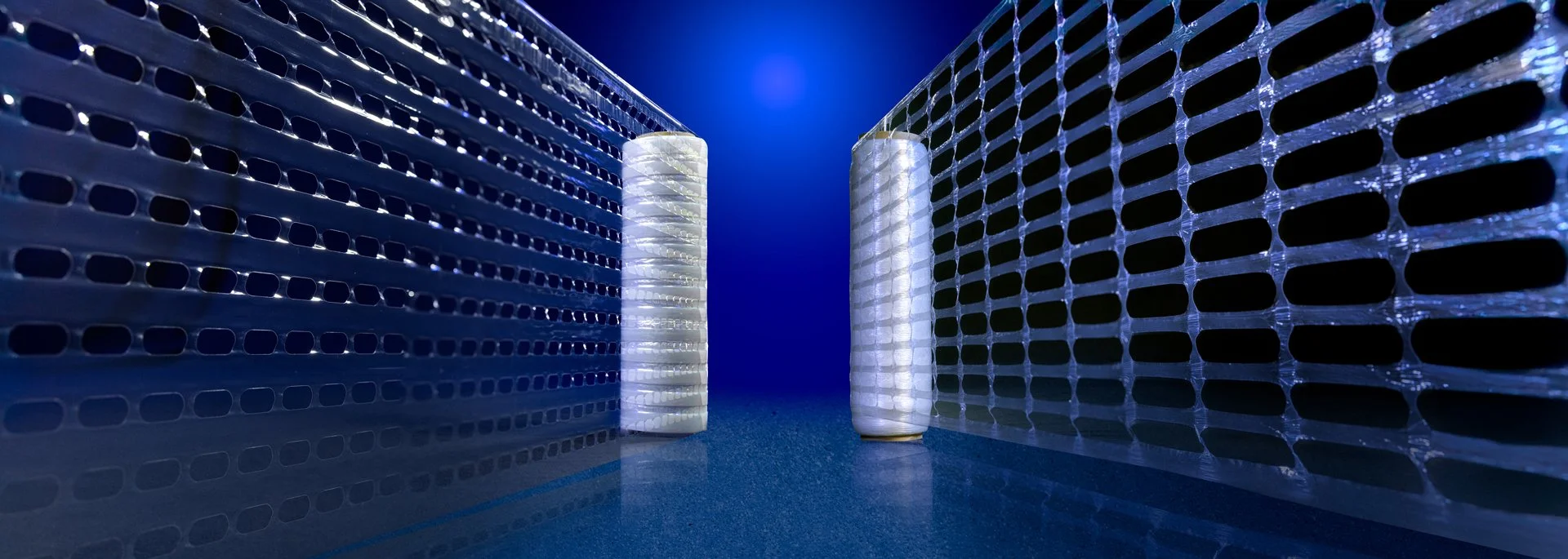

Excelerate’s Perforated, Ventilated, Breathable, Vented Pallet Wrap

What Makes Perforated Pallet Wrap Different?

ExcelAir perforated film is engineered with airflow channels that allow pallets to breathe. This ventilation offers critical benefits across industries:

Faster product cooling – up to 50% quicker in chilled and frozen supply chains

Reduced condensation – no more wet packaging or damaged labels

Greater pallet stability – tested on loads up to 1,500kg

Plastic savings – use less film while improving performance

Proven sustainability gains – reduced waste, energy, and rewraps

Who Uses It?

Perforated pallet wrap is already transforming industries:

Fresh produce – stays fresher for longer with reduced mould and spoilage

Ready meals & frozen foods – cool faster, speeding up despatch

Cheese & dairy – pallets maintain stable chilled conditions

Beverages & cans – eliminate condensation in hot-fill and export processes

And many other industries… take a look at our case studies

UK Sauce Manufacturer using ExcelAir perforated pallet wrap to eliminate cooling delays in despatch operations

Why It Matters for Your Business

Every failed pallet costs money: damaged packaging, rewrap labour, delivery delays, rejected loads. Switching to ExcelAir isn’t just about sustainability – it’s about safeguarding margins and brand reputation.

Final Word

If you’re still relying on solid pallet wrap, you could be losing thousands each year to inefficiency and product losses.

👉 Learn more about the UK’s most advanced perforated pallet wrap and see how ExcelAir can transform your operation.